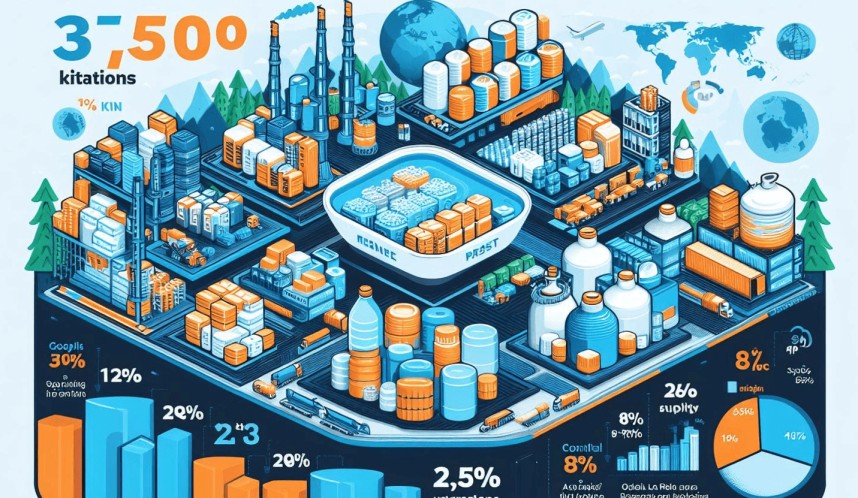

Polyethylene Terephthalate (PET) resins Capacity Overview

Global Polyethylene Terephthalate (PET) resin capacity crossed 37,500 kilotons in 2023, up nearly 35% from 2016. More than 60% of the supply resides in Asia Pacific, followed by North America and Central & Eastern Europe, each accounting for a 12% and 8% share, respectively. Prismane Consulting estimates that the global Polyethylene Terephthalate (PET) resins capacity is anticipated to surpass 45,000 kilotons by 2032, with the majority of the plant additions expected in China. Between 2016 and 2022, plant operating rates globally averaged 77% and are expected to remain in the 80s over the forecast period 2023-2032.

Polyethylene Terephthalate (PET) resins Capacity by Company

Indorama Ventures is the largest producer of Polyethylene Terephthalate (PET) resins, operating 20 active plants (including joint ventures) running across 14 countries, with a total annual production capacity exceeding 5,900 kilotons in 2022. It is followed by Alpek, which independently and via its subsidiary DAK Americas, operates 10 plants in 7 countries, with annual capacity exceeding 3,200 kilotons. Chinese producers Sanfangxiang Group & Yisheng Petrochemical are jointly the third largest producers each with a share of 7%, followed by Zhejiang Wankai New Materials at 6% share. Together, these five companies control 45% of the global Polyethylene Terephthalate (PET) resin supply.

Global PET Resins Capacity

Polyethylene Terephthalate (PET) Resins Capacity by Region

With a capacity exceeding 23,600 Kiloton, Asia Pacific is the largest producer of Polyethylene Terephthalate (PET) Resins globally. The majority of the supply in the region resides in China, which accounts for a 64% share. Other producers in the region include India, Taiwan, South Korea, Thailand, Vietnam, Indonesia, Pakistan, Malaysia, and Japan. Chinese PET capacity has grown from 7,700 Kiloton in 2016 to its current levels, as a result of strong demand of PET from the Food & Beverages, and Packaging end-use industries. Major producers operating in the country include Jiangsu Sanfangxiang Industrial Group, Yisheng Petrochemical, Zhejiang Wankai New Materials, China Resources Changzhou Petrochemical (CRC), and Jiangyin Chengxing Industrial Group. Major plants projected to come in the forthcoming years include Zhejiang Petrochemical Daishan, which is expected to bring onstream its 2,000 Kiloton/annum plant at Daishan, Zhejiang in 2026.

India is the second largest Polyethylene Terephthalate (PET) resin producer accounting for over 10% of the regional market. Key Polyethylene Terephthalate (PET) resin producers in India include Reliance Industries, IVL Dhunseri Petrochem (Indorama & Dhunseri joint venture), JBF, and Chiripal Poly Films. Chiripal commissioned its 220 Kiloton/annum plant at Ahmedabad, Gujarat, in 2017.

Taiwanese Polyethylene Terephthalate (PET) Resins supply is split between four producers: Far Eastern Textile, Shinkong Synthetic Fibers, Nan Ya, and Lealea Enterprise. SK Global Chemical and Lotte Chemical collectively represent more than three-quarters of South Korean capacity.

USA, Mexico, and Canada collectively have Polyethylene Terephthalate (PET) Resins capacity exceeding 4,400 Kiloton in 2022. Five producers currently operate in the USA: DAK Americas (subsidiary of Alpek), Indorama Ventures, Far Eastern New Century (FENC), Nan Ya Plastics Corporation, and Polyplex. DAK Americas is the sole producer in Canada, while Mexican supply is split between DAK Americas, Indorama Ventures, and M&G.

Global PET Resins Capacity, By Region - 2023

Oman, Egypt, UAE, Saudi Arabia, Iran, South Africa, Nigeria, and Tunisia are all Polyethylene Terephthalate (PET) resin manufacturers operating in Middle East & Africa each housing one plant. SABIC reduced its plant capacity from 750 Kiloton to 420 Kiloton in August 2017 for cost optimization. Hosaf (Safripol) expanded its Durban plant in South Africa to 240 Kiloton/year in 2017.

Brazil & Argentina are the only producers of Polyethylene Terephthalate (PET) resins in Central & South America, with annual capacity exceeding 1,100 Kiloton. Two M&G plants operational in Pernambuco, Brazil, were each bought by Indorama Ventures and DAK Americas. DAK Americas also operates a plant in Zarate, Argentina.

Russia is the largest producer of Polyethylene Terephthalate (PET) resins in Central & Eastern Europe. Safpet, POLIEF (a subsidiary of SIBUR), and Tatneft are key producers in the country. With three operating players, Köksan, Indorama Ventures, and Sasa Polyester, Turkey is the second largest Polyethylene Terephthalate (PET) resin producer in the region. Indorama Ventures has two plants, each in Corlu and Adana, however, its Adana facility has been non-operational for many years. The Corlu plant, with an annual production Polyethylene Terephthalate (PET) resins capacity of 256 Kiloton, was acquired by the company from Polyplex Europa Polyester Film. Sasa Polyester commissioned its 315 Kiloton/year Polyethylene Terephthalate (PET) resins plant at Adana in 2020 and has been operating since. Köksan, meanwhile announced the expansion of its existing Gaziantep facility by 216 Kiloton.

Lithuania, Poland, and Greece are other PET resin manufacturers in Central & Eastern Europe. Lithuanian supply is split between Indorama Ventures and Neo Group, both operating their plants in Klaipeda.

Polyethylene Terephthalate (PET) resins supply in Western Europe is split between Spain, Germany, Belgium, Netherlands, UK, and Italy. Indorama operates its plants in four of these countries, although only three were operational as of 2022. Alpek reduced the capacity of its Wilton, Teesside plant in the UK in 2022 to 220 Kiloton/annum, citing low margins.

High energy prices, increasing Chinese supply, and tepid domestic demand is weighing down on European PET value chains, affecting their cost competitiveness. As a result, several manufacturers are mothballing PTA plants and are buying raw materials instead. JBF-RAK’s recent decision to halt PET production at its Geel, Belgium plant is reflective of the challenging market conditions. The Russia-Ukraine war has pushed European energy prices up and increased production costs. Consequently, PET prices in the region have increased, prompting consumers in the region to source PET volumes from foreign markets like China. Out of around 4,000 Kiloton of annual demand for PET in Europe, nearly 800 Kiloton is catered to via imports. With costs still remaining elevated, analysts estimate imports to the region to increase up to 1,400 Kiloton. With growing Asian supply, forthcoming years are likely to see some restructuring in the European PET business.