Aerospace Composites Market Overview

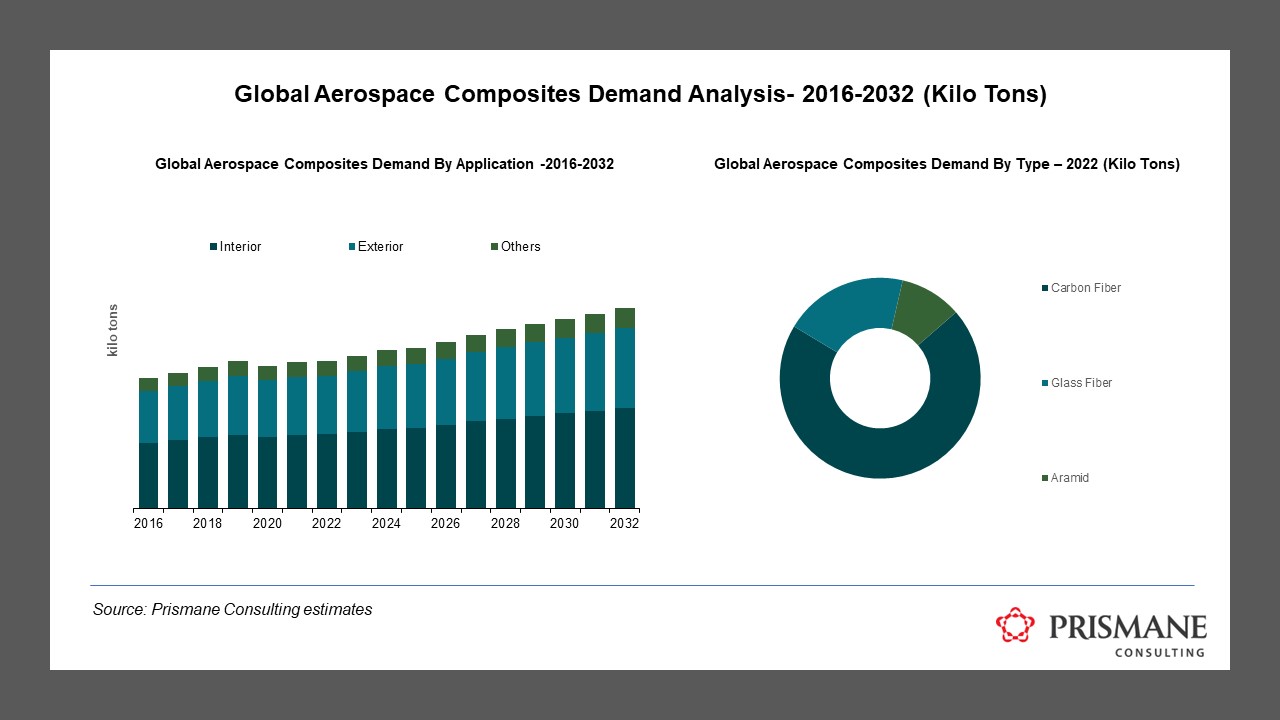

The global Aerospace composites market was estimated to be over 40 kilo tons, has experienced consistent growth at an aggregate rate of 7% annually over the past five years.. Global Aerospace composites demand is projected to cross 55 kilo tons by 2032, with a growth rate of 4% between 2023-2032. The demand for Aerospace composites was affected in 2020 with market contracting mainly because of COVID-19 and slowdown in major economies.

However, the demand is estimated to recover steadily and reach its pre-COVID level in the coming years. In 2022, global Aerospace composites industry demand exhibited strong growth, resulting in an improvement in the global Aerospace industry. This can be attributed to the increase in global demand for both Aerospace and military aircrafts. Composites are used in these aircrafts in their exterior, interior and critical engine parts.

In terms of Aerospace composites market by region, North America is the biggest market accounting for more than 40% of the global market. Like other industries including automotive and chemicals, the region has not witnessed any significant shift be of composite manufacturers and aerospace industry base to Asia-Pacific.

Innovating Aviation: The Power of Aerospace Composites

The world of aviation is evolving at a rapid pace, and aircraft manufacturers are on a relentless quest for innovation. Their mission? To enhance efficiency, reduce noise, and slash operational costs for airlines. At the heart of this revolution is a surprising ally: plastics. The integration of plastics into the aerospace industry is revolutionizing the way we fly, primarily driven by the magic formula of weight reduction and efficient processing.

A New Era of Materials: Aerospace Composites

Step onto the runway of modern aviation and space exploration, and you will encounter aerospace composites – the unsung heroes shaping the future of flight. These materials, known for their remarkable blend of strength and feather-light weight, weave a tale of innovation. They are crafted by reinforcing fibres within a matrix material, granting them exceptional rigidity and resilience. Imagine aircraft and spacecraft that effortlessly combine strength with agility – aerospace composites are making it a reality.

Categories Unveiled: Fibre Types and Dominance

As we delve deeper into the aerospace composites realm, we encounter a classification based on fibre types: glass, carbon, and aramid fibres. Here, carbon fibre composites emerged as the rock stars of 2022, commanding the global aerospace composite stage. Their exceptional resistance properties contribute to weight reduction, while their easy processability and thermal attributes make them champions of cost-effective large-component production. These composites are like master artisans, crafting precision without the need for extensive assembly.

Crafting the Future of Airframes and Engines for Greener Skies and Lightweight Propulsion

Composite materials are the structural backbone of an aircraft, constituting roughly half of its primary structure. Think fuselage and wings. The magic of these materials lies in their lightweight nature and capacity to create intricate components. It is akin to crafting a masterpiece, where leveraging plastics magnifies efficiency and performance across airframes, engines, and structures.

With global regulations spotlighting environmental sustainability, the demand for eco-friendly aircraft propulsion systems is soaring. Enter lightweight, high-performance materials like advanced composites. Among them, carbon fibre shines bright with attributes like exceptional strength, stiffness, and reduced weight. It is a preferred choice, boasting a strength-to-weight ratio that leaves traditional fibreglass in the dust. The environmental tides are turning, and aerospace composites are riding the wave.

Leaders of the Revolution: Manufacturers at the Helm

Driving the innovation juggernaut are leading manufacturers: Solvay, Owens Corning, Teijin Limited, SGL Carbon, Hexcel Corporation, and Toray Industries. These titans of the industry are at the forefront of composite technology, steering advancements that shape the industry s future.

North America's Sky-High Stature

Across the Atlantic, North America s shines brightly in the aerospace composites market. Fuelled by stringent carbon emission regulations and a robust aerospace industry, the United States takes centre stage. With a growing aerospace and defence workforce, the nations skies are full of potential. In 2021 alone, the aerospace industry s revenue surged, testament to its unwavering growth trajectory.

The likes of Boeing and Airbus are driving the charge, integrating aerospace composites with surgical precision. Boeing s 787 model boasts an airframe structure composed of 50% advanced composite materials, leading to a 20% reduction in weight compared to traditional aluminium designs. The results? Reduced maintenance time, corrosion, and fatigue – and ultimately, more cost-effective, and eco-friendly air travel. The Airbus A350 XWB model marries carbon fibre composites with wings, enhancing toughness and strength while shedding weight. Even China s COMAC, with their C919 commercial aircraft, has embraced composites, further cementing the materials transformative impact.

For Further Information, Please click here

To View Sample, Please click here

For more details on Aerospace Composites Market, please contact us at sales@prismaneconsulting.com